Products

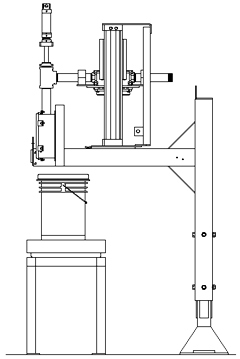

AMSTELTop Fill Pail/Drum Filler

AMSTEL Top Fill Pail Filler provide a reliable and quick way to fill non-foamy products. The model T-5 is designed to provide accurate liquid filling of upto 50 kg pails.

Standard Features

- User friendly menu driven system

- Recipe programming & saving of all fill set points

- Slow-fast-slow fill mode programming

- Automatic preact calculation

- Resume capability to continue filling aborted fill cycles

- “No pail no fill” feature to prevent product spillage

- Net weight over/under fill monitoring

- Weight indicator control, zero, tare, gross/net

- *Two ball valve system for slow-fast-slow fill modes

- *Hand operated lever for fill start/stop operation

Standard construction

- 304 stainless steel structural construction

- 316 stainless steel wetted parts (lance & pipe)

- Powder coated carbon steel control NEMA-4 enclosures

- Two piece 316 stainless steel ball valves Teflon seals & seats

- Carbon steel low profile scale case

- Raised platform

- Sealed load cells

- 1 part in 5,000 resolution Upto 50kg capacity

SPECIFICATIONS

- Accuracy: ±0.2%

- Output (approx): Dependent on application

- Height (approx): 2.1m

- Depth (approx): 2.1m

- Width (approx): 1.2m

- Operating Temp: 0°C to 50°C

- Overload Capacity: 150%

- Working Pressure: 6 bar (0.6Mpa)

- Air Consumption: 30 litres per cycle

- Electricity Supply: 230V AC, 50Hz

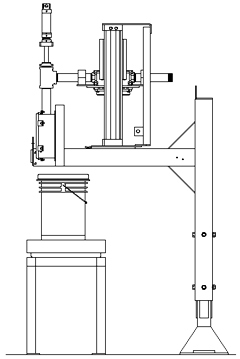

AMSTEL T-55 Top Fill Drum Filler

AMSTEL T-55 Top Fill Drum Filler provide a reliable and quick way to fill non-foamy products. The model T-55 is designed to provide accurate liquid filling of upto 500 kg drums.

Standard Features

- User friendly menu driven system

- Recipe programming & saving of all fill set points

- Slow-fast-slow fill mode programming

- Automatic preact calculation

- Resume capability to continue filling aborted fill cycles

- “No drum no fill” feature to prevent product spillage

- Net weight over/under fill monitoring

- Weight indicator control, zero, tare, gross/net

- *Two ball valve system for slow-fast-slow fill modes

- *Hand operated lever for fill start/stop operation

Standard construction

- 304 stainless steel structural construction

- 316 stainless steel wetted parts (lance & pipe)

- Powder coated carbon steel control NEMA-4 enclosures

- Two piece 316 stainless steel ball valves

- Teflon seals & seats

- Carbon steel low profile scale case

- Raised platform

- Sealed load cells

- 1 part in 5,000 resolution Upto 500kg capacity

SPECIFICATIONS

- Accuracy: ±0.2%

- Output (approx): Dependent on application

- Height (approx): 2.1m

- Depth (approx): 2.1m

- Width (approx): 1.2m

- Operating Temp: 0°C to 50°C

- Overload Capacity: 150%

- Working Pressure: 6 bar (0.6Mpa)

- Air Consumption: 30 litres per cycle

- Electricity Supply: 230V AC, 50Hz

ISO CERTIFIED