Products

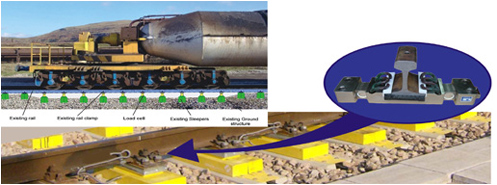

Torpedo Weighing Rail Scale

A PC is used to record and process the weights including supplementary data Load cells determine the weight of the pig iron that is leaving the blast furnace for the steel plant. The torpedo weight can be measured.

Application

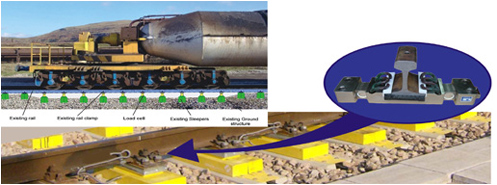

The AMSTEL Torpedo Weighing Rail Scale is a pit less state of the art static weighing scale for hot torpedo cars. High – precision , high–temperature load cells are installed between the existing rail clamps and the existing wooden or concrete sleepers. They reliably transmit all vertical forces applied by the torpedo car wheels , with a high degree of accuracy and repeatability. The weighing system is installed without a foundation and can be installed without additional effort during a normal track maintenance period.

A PC is used to record and process the weights including supplementary data Load cells determine the weight of the pig iron that is leaving the blast furnace for the steel plant. The torpedo weight can be measured.

- as a static weighing system at the tapping position of the blast furnace.

- by weighing half of the entire torpedo car.

Functions

- Optimise the material flow to the steel plant by weighing the pig iron that you are receiving.

- Accurately fill each torpedo car by adjusting the nett weight of pig iron arriving from the blast furnace.

- Manage the slag deposit onto the refractory surface for better maintenance cycles.

- Improve the tapping process by controlling the overfill.

Features

- Static weighing of hot torpedo cars.

- High temperature load cells for operating temperatures up to + 200ºC.

- Load cell design based on existing rails.

- Precise determination of hot metal output.

- Pitless and gap – free design.

- Large measuring area.

- High accuracy.

- Installation without foundation.

- Capacities up to 800 tons.

ISO CERTIFIED