AMSTEL offers Weigh Feeders to feed bulk solids continuously to the process In a Weigh Feeder, product is fed as a continuous band onto a conveyor belt, through an inlet slide gate or automatic pre-feeder. Load cells under the belt continuously measures the weight of the product over a defined length of belt. The Weigh Feeders are suitable for installation in industrialized environment with light & heavy duty conditions respectively. They are specifically designed to provide dependable service with minimum maintenance and care. Heavy duty, Long life components are selected to assure a stable and distortion free compact assembly capable of withstanding tough industrial conditions.

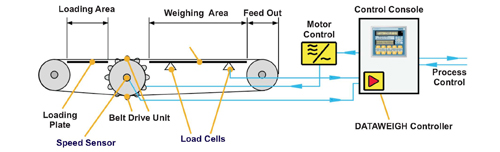

High quality measurement and control electronics allow both convenient operation and extensive monitoring, assuring high accuracies of feed. Weigh Feeders are able to control in continuous mode, the flow of the discharged material maintaining the instantaneous flow rate constant with respect to the set rate. The weight is measured directly at the weighing zone sensed by a centrally placed weighing idler which is placed on two numbers of high precision load cells. A digital tachometer detector generates the signal in proportion to the speed of the belt. The AMSTEL DATAWEIGH series controller continuously compares the actual weight with the set point weight, and automatically adjusts the motor speed to either increase or decrease belt speed, in order to maintain a constant feed rate. Any variation in the density of the material is reflected as a change in belt loading, which is compensated for by adjusting the belt speed.

High quality measurement and control electronics allow both convenient operation and extensive monitoring, assuring high accuracies of feed. Weigh Feeders are able to control in continuous mode, the flow of the discharged material maintaining the instantaneous flow rate constant with respect to the set rate. The weight is measured directly at the weighing zone sensed by a centrally placed weighing idler which is placed on two numbers of high precision load cells. A digital tachometer detector generates the signal in proportion to the speed of the belt. The AMSTEL DATAWEIGH series controller continuously compares the actual weight with the set point weight, and automatically adjusts the motor speed to either increase or decrease belt speed, in order to maintain a constant feed rate. Any variation in the density of the material is reflected as a change in belt loading, which is compensated for by adjusting the belt speed.

SPECIFICATIONS

- Type : Gravimetric belt weigh feeder

- Belt Width : 500mm to 2000mm

- Control Range : 1 : 10

- Temperature Limit : 0'C to 100'C

(higher temperatures available depending on material and other conditions) - Direct Weighing System : Direct multiple cell in the main stringer for permanent alignment weighing system without levers or counter balance weights. Load cells are accessible for inspection.

- Infeed Hopper Type : T type, U type (mass flow vibratory hopper), VLIC type, S type (Setting Chamber)

- Capacities : 500 kgs/hr to 300 TPH

- Accuracy : +/- 0.5%

- Control System : DATAWEIGH Controller

- Electrical Power Requirements : Instrumentation-230 VAC,

Power-230/460 VAC - Frame : Heavy-duty rugged frame with idlers directly mounted in the main stringer for permanent alignment

- Digital Speed Sensor : Sensor is mounted between motor and reducer to provide high frequency and symmetrical speed signal