Products

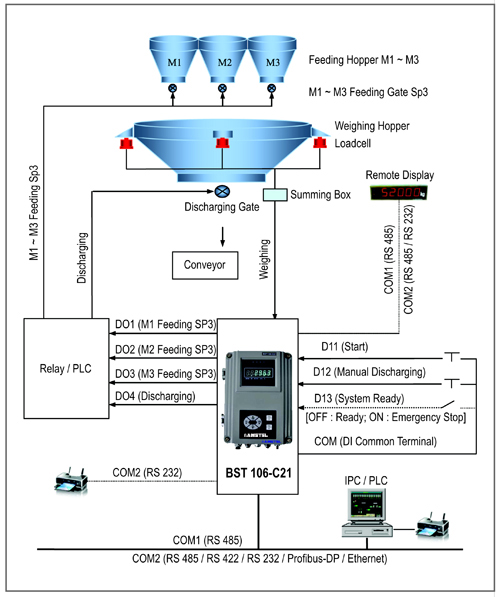

Automated Batching System

Application

The control system allows blending of multiple products into a single weigh bin.The achievable weighing accuracy is commensurate with that of a static weighing system. Up to ten components may be automatically batched in a preset sequence, according to a programmed recipe. Semi-automatic and manual modes of operation may also be selected. In-flight compensation, agitation and settling time is selectable per product. The stand-alone batching system can store up to 10 recipes, each with up to 10 components. When under computer control (SCADA, PLC etc) the number of recipes is unlimited.

Main Features Of Weighing Controller

- Data calibration and load calibration facility.

- Support industry configuration software.

- Weighing reports can be printed.

- EMC design with high anti-jamming capability, suitable for industrial environment.

- Menu & shortcut mode operation with key tone.

- ARM CPU system with high arithmetic speed.

- 24-bit High-precision and high-speed sigma-delta A/D conversion module with 130,000 internal code [AD value] used and 200Hz sampling frequency.

- Special filtering algorithm for ensuring weighing stability and accuracy when there is strong vibration on the load receptor, and rapid response capability with changes in weight signal.

- Auto-locking, key-locking, key-unlocking, digital setting & calibration and I/O Testing functions

- 1 optional and definable analog signal output ( 4-20mA )

- 3 normally open switch inputs [DI] and 4 normally open relay or transistor switch outputs [DO].

- 2 optional communication ports for linking to PC/PLC, remote display or operation terminal, serial printer, wireless module, etc.

- With the multitasking mode, the weighing & control process will not be interrupted by parameter setting and the other operations.

ISO CERTIFIED