Description

While fully automatic N95 mask manufacturing machines have higher output, they are highly sophisticated and very costly, requiring skilled technicians for rectification during breakdown. Due to the restrictions in international travel, a major breakdown can lead to a major loss of output. Alternatively, if the individual operations are performed by different machines, although the labour cost is higher, rectification during breakdown is much easier. Labour is cheap in India, compared to other countries.

There is currently a huge demand for N95 ( FFP2 ) masks in India, and is also expected to remain in the future, due to the Covid-19 pandemic

Reusable respirators ( masks ) have different standards around the world.

The performance standards are as follows:

N95 ( USA )

FFP2 ( INDIA )

KN95 ( CHINA )

MACHINES REQUIRED FOR ALL STAGES FOR MANUFACTURE OF N95 ( FFP2 ) MASKS

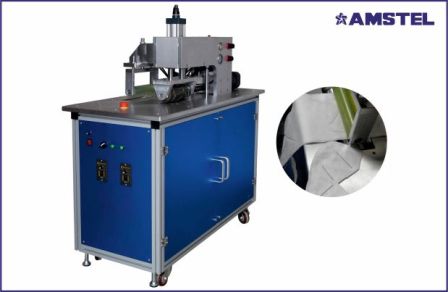

Stage 1 : Mask Blank Making Machine for Blanking & Sealing

Stage 2 : Mask Aluminium Nose Bridge Welding Machine ( optional )

Stage 3 : Ear-loop Welding Machine

Stage 4 : Mask Edge Sealing Machine.

The 15 kHz 2600W frequency ultrasonic welding system installed in the N95 mask blank making machine is much costlier, has much higher power, and ensures much higher N95 mask output, compared to conventional 20 kHz 2000W systems.

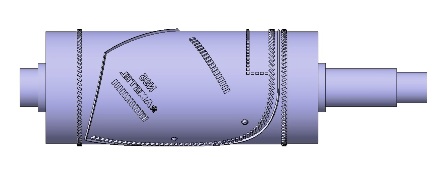

Information like the buyer's logo, FFP2, ISO and CE can be engraved in the cutting roller of the N95 mask blank making machine. The N95 will have the buyer's logo, FFP2, ISO and CE along with N95 engraved on the surface, so separate printing of information on the mask is not required. We can customize design, as per buyer's requirement