Products

AWC Dynamic (In-Motion) Axle Weighbridge

Application

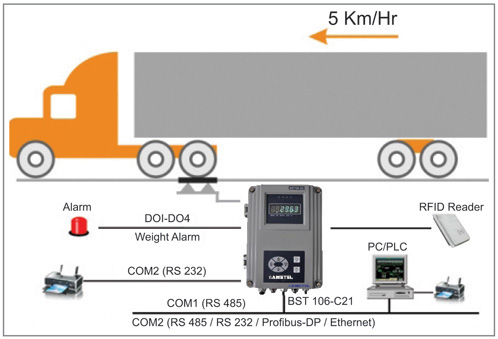

The AWC Dynamic (In-Motion) Axle Weighbridge is designed to be an economical and convenient solution for measuring the weight of moving trucks.

The AWC JUMBO Dynamic (In-Motion) Axle Weighbridge is a system consisting of individual weighing platforms which measure the load on each wheel of a dumper truck dynamically or statically. Its modular design enables any possible truck axle configuration or model of mining dumper truck.

A large external LED display is available for quick and easy viewing of the weights. A traffic light can be used with the large display to tell the driver when to move on and off the weighbridge.

Main Features

- Capacities up to 200T.

- Simple operation.

- Save time by weighing vehicles on the move.

- High-quality load cells IP 68.

- Sturdy steel construction.

- Dynamic and static operation selectable by user.

- Automatic addition of all axle loads.

- Suitable for all vehicle types with different numbers of axles.

- One weighing platform of size 3 M X 0.75 M or two weighing platforms of size 1.2 M X 0.8 M or 3 M X 2.4 M.

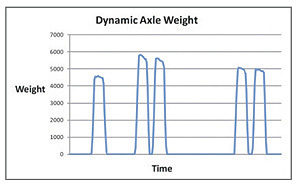

- Dynamic ( in motion ) weighing.

- Travel speed up to 5 km / hr.

- Weighing up to 24 tons per axle. Accuracy in dynamic weighing +/- 1% of FSR.

- Under and over load selectable by user with alarm facility.

- ARM CPU system with high arithmetic speed.

- 24-bit high-precision and high-speed sigma-delta conversion module with 130,000 internal code [AD value] used and 200 Hz sampling frequency.

- EMC design with high anti-jamming capability, suitable for industrial environment.

- Menu & shortcut mode operation with key tone.

- Auto-locking, key-locking, key-unlocking, digital setting , calibration and I/O testing functions.

- 1 optional and definable analog signal output (4-20 mA ).

- 3 normally open switch inputs [DI] and 5 normally open relay switch outputs [DO].

- Support industry configuration software.

- The historical axle weighing records can be queried and printed.

- The present axle weighing record can be printed automatically and manually.

- 2 optional communication ports for linking to PC/PLC, remote display and operation terminal, serial printer, wireless module, etc.

- Special filtering algorithm for ensuring weighing stability and accuracy when there is strong vibration on the load receptor, and rapid response capability when the weight signal changes.

- With the multitasking mode, the weighing and control process will not be interrupted by parameter setting and the other operations.

- Once the internal temperature exceeds 45°C, the cooling fan of weighing controller will work automatically to avoid overheating under the high ambient temperature.

- Optional RFID reader with Tags and traffic lights.

ISO CERTIFIED